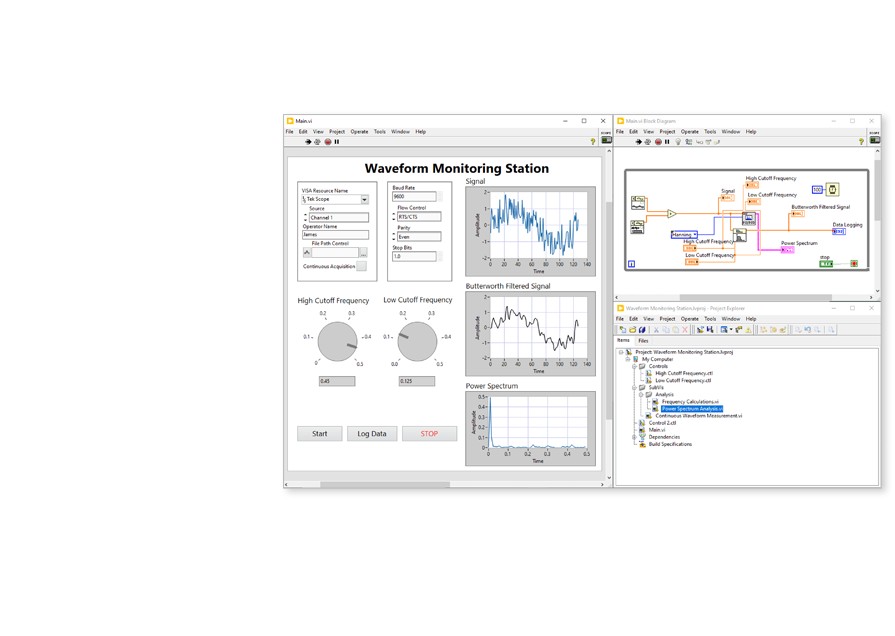

Get more from LabVIEW and LabVIEW+

LabVIEW helps you work more quickly. Spend less time developing tests, automating instruments, analyzing data, and generating reports.

Featured products

NI Connect Austin

May 20–22, 2024

Discover the latest test technologies and trends at NI Connect 2024. Network with industry leaders and learn new approaches to help drive innovation and business results across your organization.

Build What's Next

NI offers the hardware, software, and services that help you turn real-world data into insights that drive your business decisions. Choose from products for desktop design and prototyping to fully automated production test systems.

Shop by Application Area

Elevate Performance with Test

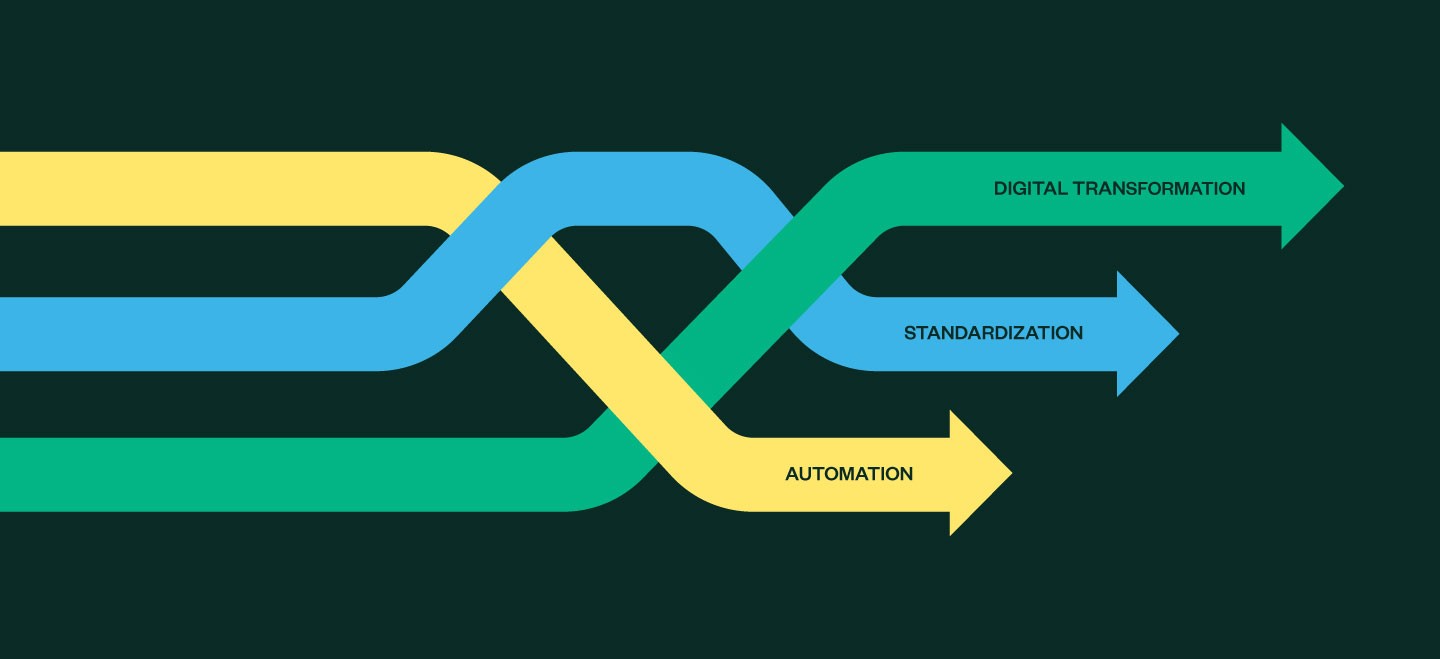

Unlocking the full benefits of test isn’t just about using a better tool. It requires an intentional strategy with automation, standardization, and digital transformation initiatives.

-

NI PERSPECTIVES

5G Isn't for You

5G isn’t for humans, but it will make human life better. As 5G extends well beyond wireless devices, let’s talk about who—or rather, what—it’s for.

NI PERSPECTIVES -

NI PERSPECTIVES

Engineering Ambitiously—from Anywhere

Providing engineers with easier remote access to tools isn’t just useful, it’s vital. Learn about the four factors that enhance productivity during uncertain times.

NI PERSPECTIVES -

NI PERSPECTIVES

Breaking Out of Testing Silos

Standardizing your test approach is easier than you may think, and the benefits are worth the investment. Learn how to put standards in place to reduce cost and save time.

NI PERSPECTIVES -

NI PERSPECTIVES

Be Prepared for an Uncertain Future

The modern lab isn’t just a renovated workspace—it’s a living and breathing nucleus that bolsters your organization and elevates your tools, people, and processes.

NI PERSPECTIVES