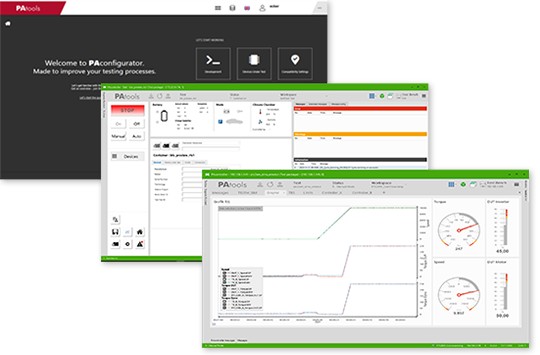

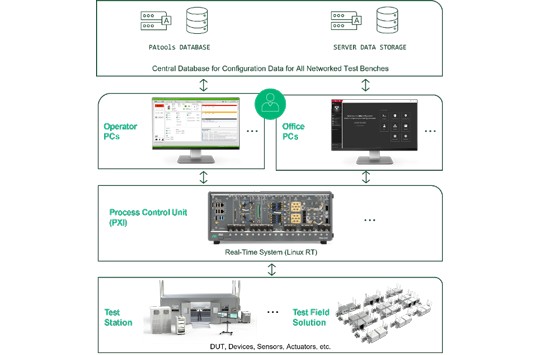

PAtools is a comprehensive test bench automation software for battery cell, module, or pack systems, among others. With a user-friendly interface, automation capabilities, and advanced data analysis, PAtools elevates product quality in the following ways:

- Facilitates the development of effective testing procedures for new EV components as e-motor or e-axle components or battery technologies.

- Enhances result interpretation, leading to improved product design and shorter testing cycles.

- Boosts accuracy, streamlines procedures, and accelerates product launches.